Thick and Thin Ceramic or Powdered Metal Sheet Forming Featuring High Density or Engineered Porosity

RTI leverages decades of experience utilizing proprietary technologies and other industry processes to provide clients with

application specific developments for the ceramics, electronics, and energy storage industries.

Applications Include:

Electrochemical Electrodes, Filter Plates, Gas Permeable Metal Membranes and Ceramic Membranes, Wear Plates, Insulators,

Heating Elements, Powdered Metallurgy, Piezeoeltrics, Ceramic Armour, High Voltage Capacitors, Structural Ceramics

We can Assist you in all Stages From Process Development and Toll Manufacturing to the Installation of a High Volume Manufacturing Line.

Fabricating Green Tape, Ceramic Tape, Thick Tape, Dense Tape, and Porous Tape

RTI can assist with process development:

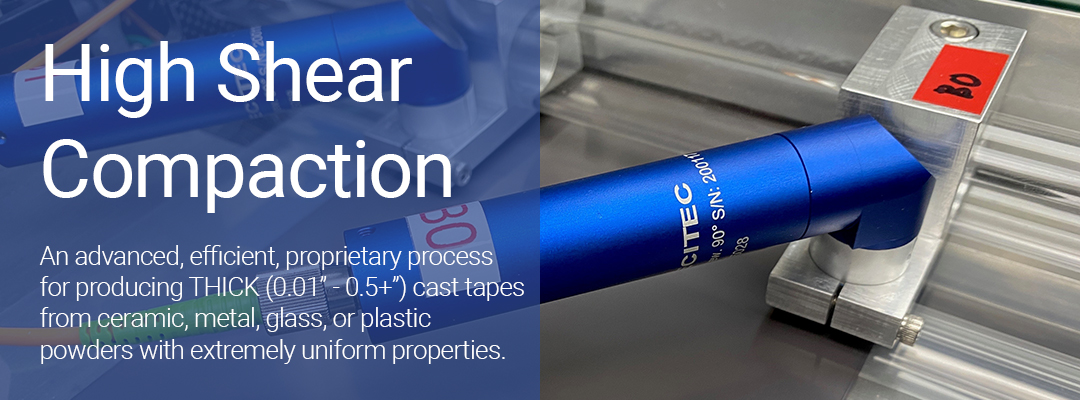

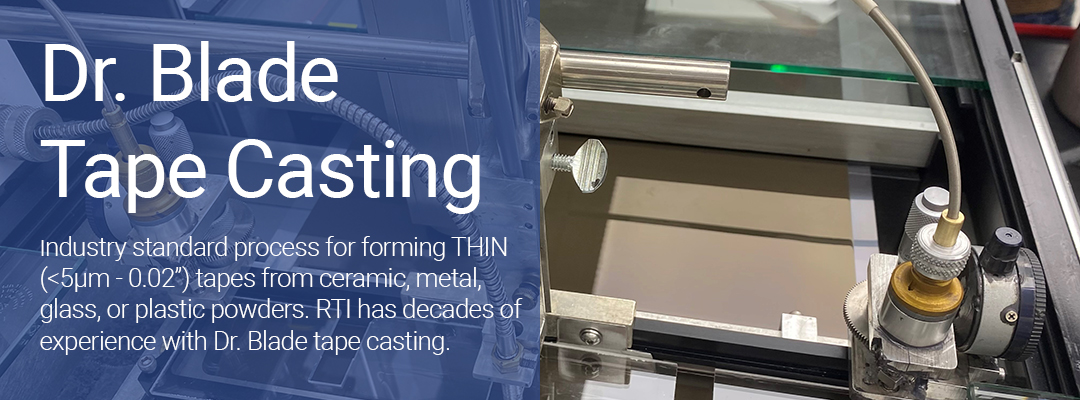

We maintain a development laboratory where we can take your powders and produce tapes to your specifications at very low cost utilizing our HSC Tape Forming Process or Dr. Blade Tape Casting Process.

RTI can be your out-sourced green tape fabricator:

RTI specializes in providing out-sourced tape tolling services. We can process your tape in development quantities while assisting you with in-house capabilities.

RTI offers complete TURN-KEY INSTALLATIONS:

Upon completion of tape testing and verification, RTI offers complete turn-key installations from small laboratory scale to high volume fully automatic production systems. RTI can develop and construct tooling and automated processing equipment as required for each client. This includes blanking, cutting, slitting, stacking, laminating, punching, conveying, green machining, etc.

These and other technologies can be tailored to your needs for in-house manufacture or we can toll manufacture for you. The developed and installed cost of these technical innovations is much lower through the use of our out-source ceramic tape development service when compared to an in-house effort. A savings of 40% – 90% can be expected.

RTI’s development strategies and innovations will be tailored to meet your company’s market and production demands. From project onset to the technology transfer phase you have the satisfaction of knowing you’re working with a recognized leader in providing technology development. We look forward to demonstrating how our technologies can provide problem solving manufacturing options and lower your costs while increasing your company’s productivity and profitability.